MotorSilk® Engine Treatment (MSET)

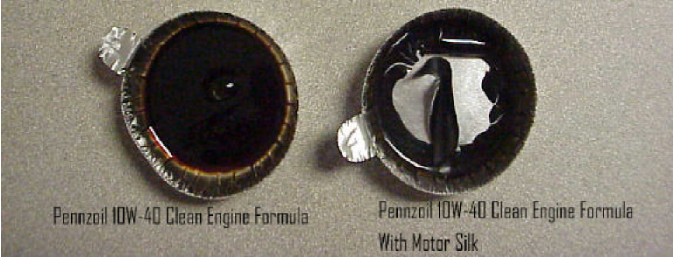

Varnish / Sludge Forming Test

Laboratory test conducted by Herguth Labs (USA)

Samples Heated for 2.5 hours @650F

Heated oil bonded to the dish surface and was a thick, tacky, viscous, varnish like material.

The same oil with MotorSilk® was dry and easily flaked off leaving no discoloration

MotorSilk® Diesel Additive (MSDA)

Pin on Disk Test to Measure Scaring

Low sulfur diesel fuel with Boron-CLS-Bond®

“Deposit control is a crucial part of brand differentiation strategies designed to enhance diesel engine performance and reduce emissions. Efficient operation of diesel engines depends on proper operation of the fuel injectors, so control of deposits in this critical area is necessary to ensure optimum performance, minimize fuel consumption and control engine smoke”. –Chevron

MotorSilk Diesel Additive (MSDA)

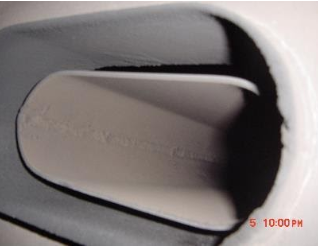

Exhaust Stack on locomotive 7501

The locomotive 7501 were treated with (MSDA).

The photos clearly depict reductions in carbon build-up in the stacks, pistons and air boxes, and other components also showed signs of cleaning.

Results from two locomotives showed that at throttle #5, horsepower increased by an average of 5.52%, and the Governor racks extended.

This cleanliness and the reduced wear would, after detailed examination will allow for the extension of service life of numerous parts, which will affect maintenance requirements and maintenance hours.

The resulted in the freeing up of resources, including capital assets, spare-part inventories, and personnel that will allow for other tasks to be performed.

Piston on locomotive 7501

Air Box on locomotive 7501